Industrial remote control systems are commonly used for crane control and hoist control in industrial settings. These systems allow operators to remotely control the movement and operation of cranes and hoists, providing flexibility and improving safety in lifting and material handling operations. Here are some specific aspects related to crane control and hoist control in industrial remote control systems:

Crane Control:

Motion Control: Industrial remote control systems enable operators to control the movement of cranes, including hoisting, lowering, slewing, and traveling motions.

Load Control: The remote control device allows operators to control the lifting and lowering of loads, ensuring precise positioning and smooth operation.

Multiple Crane Control: In scenarios where multiple cranes are used in the same vicinity, advanced industrial remote control systems can manage and coordinate the operation of multiple cranes simultaneously.

Hoist Control:

Lifting and Lowering: Industrial remote control systems allow operators to control the vertical movement of hoists, raising and lowering loads with accuracy and control.

Load Monitoring: Some systems provide load monitoring capabilities, allowing operators to monitor the weight of the load being lifted and ensure safe lifting practices.

Speed Control: The speed of hoist operations can be adjusted and controlled remotely using the remote control device, ensuring efficient and safe material handling.

Safety Features:

Emergency Stop: Industrial remote control systems for crane and hoist control incorporate emergency stop buttons or switches that immediately halt all operations in case of an emergency.

Two-Hand Control: Some systems require operators to use both hands to operate the remote control device, ensuring that their attention is focused on the control process and reducing the risk of accidental activation.

Feedback and Monitoring: Remote control systems may provide feedback to the operator, such as load weight, hoist position, or crane status, enabling better situational awareness and safer operations.

Integration and Compatibility:

Crane and hoist control systems can be integrated with various types of cranes and hoists, including overhead cranes, gantry cranes, tower cranes, jib cranes, and electric or hydraulic hoists.

Compatibility with existing crane and hoist systems is crucial to ensure seamless integration, enabling operators to retrofit remote control capabilities to their equipment.

Industrial remote control systems for crane and hoist control offer several advantages, including increased operator safety, improved precision and control, enhanced productivity, and the ability to operate equipment from a safe distance or in hazardous environments. These systems are designed to meet industry standards and regulations to ensure safe and efficient lifting operations.

Kani Xie

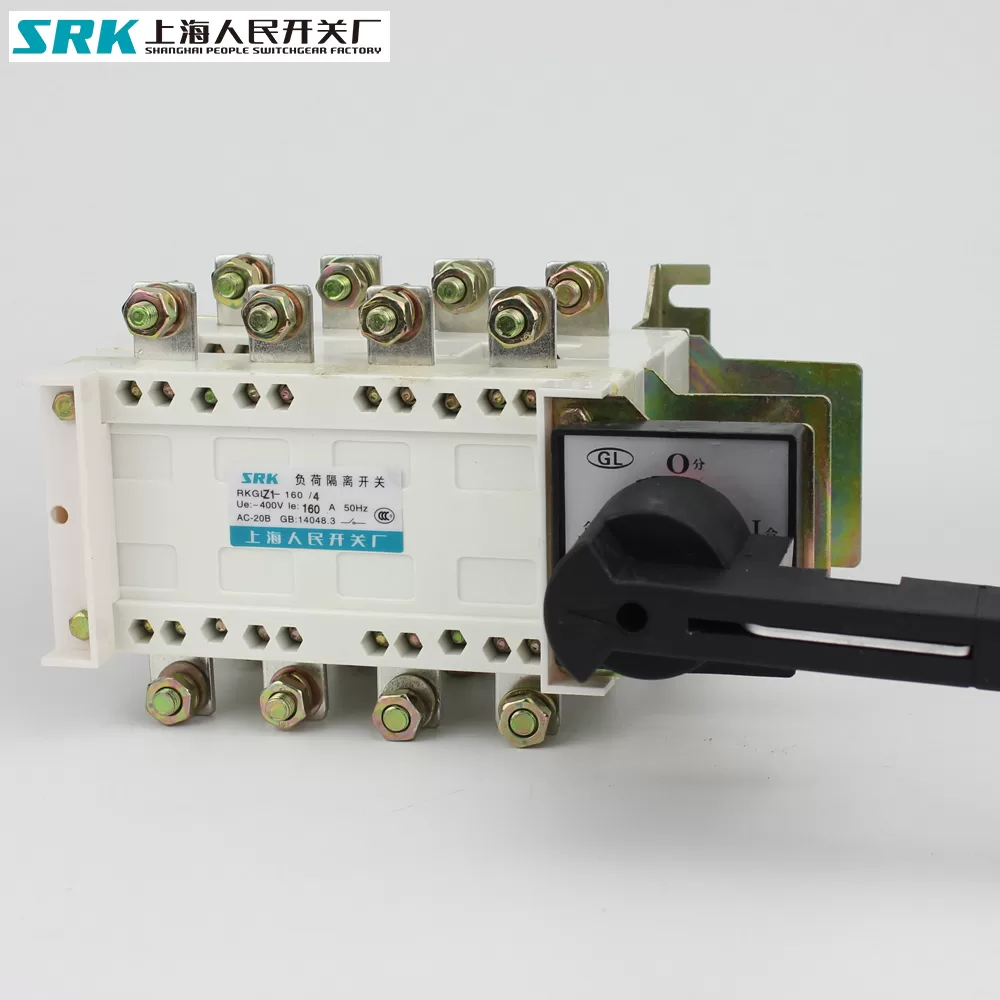

SHANGHAI PEOPLE SWITCHGEAR FACTORY

E-mail:Kani@srkswitchgear.com

Ph: 0086 13695872200

Wechat/ WhatsApp/skype: +86 13695872200