There is a lot of confusion around the industry about the difference between Relays and Contactors.

Relays are used to control contacts of an electrical circuit due to a change of parameters or conditions in the same circuit or any other associated circuit.

Contactors, on the other hand, are used to interrupt or establish connections in an electrical circuit repeatedly under different conditions.

So what’s similarity between Contactor and Control Relay?

Contactor and Control Relay work on same principle. They are basically electrically operated solenoid switches that are designed for the switching or control the loads. Moreover, both of them are constructed in a similar way:

Both, contactor and control relay, have a top housing which have set of normally open or normally closed contacts. The bottom housing in both cases, have a set of magnet and coil with external cover to protect all the internal parts.

What Makes Contactors Different from Relays?

The textbook definitions are similar enough it doesn’t really help us. Both perform the same task of switching a circuit! So What really differentiates the two devices?

1. Load Capacity

Relays are generally classified as carrying loads of 10A or less, while a contactor would be used for loads greater than 10A, but this definition, while simple, gives an incomplete picture. It leaves out any physical differences, or standards.

2. Open/Closed Contact Standards

Contactors are almost exclusively designed to operate with normally open (Form A) contacts. Relays on the other hand can and often are both Normally Open and/or Normally Closed depending on the desired function. This means that with a contactor, when it is de-energized there is (typically) no connection. With a relay there very well could be.

3. Auxiliary Contacts

To confuse things a bit, contactors are often fitted with auxiliary contacts which can be NO or NC however these are used to perform additional functions related the control of the contactor. For example, the contactor may transmit power to the motor, while the auxiliary contact is in the control circuit of the motor starter and commonly used to turn on a pilot light indicating the motor is operating.

4. Safety Features (Spring-Loaded Contacts)

Because contactors are typically carrying high loads, they often contain additional safety features like spring-loaded contacts to help ensure the circuit is broken when de-energized. This is important because in high load situations contacts can weld themselves together. This can create the dangerous situation of a circuit being energized when it is supposed to be off. Spring-loaded contacts help to reduce this chance, as well as ensure all circuits are broken at the same time. Since relays are typically for lower power, spring-loaded contacts are much less common.

5. Safety Features (Arc Suppression)

Another safety feature commonly included in contactors, due to the high loads they typically carry, is arc suppression. Magnetic arc suppression works by extending the path an arc would have to travel. If this distance is extended further than the energy can overcome, the arc is suppressed. Since relays aren’t designed for high loads, arcing is less of a concern and arc suppression is much less common on relays.

6. Safety Features (Overloads)

Lastly, contactors are commonly connected to overloads that will interrupt the circuit if the current exceeds a set threshold for a selected time period, usually 10-30seconds. This is to help protect the equipment downstream of the contactor from damage due to current. Overloads are much less common on relays.

Contactor vs Relay Applications

Contactors are typically built for and used in 3-phase applications where a relay is more commonly used in single phase applications. A contactor joins 2 poles together, without a common circuit between them, while a relay has a common contact that connects to a neutral position. Additionally, contactors are commonly rated for up to 1000V, while relays are usually rated to only 250V.

Choosing Between Contactors and Relays for Your Application

When selecting between the two, some very general rules you can follow to help

When to Use a Relay:

10A or less current

Up to 250VAC

1 phase

When to Use a Contactor:

9A or more current

Up to 1000VAC

1 or 3 phase

Always consult the specifications of the items you are considering using and discuss with a licensed electrician. This is for informational purposes only.

In practice, you should be looking at the function as well. For any circuit where an overload condition could occur, and a failure to de-energize the circuit will create a dangerous condition, then a contactor is likely the best choice because of the additional safety features. For switching low power, when the additional safety features of a contactor are not necessary, a relay is typically the more economical choice.

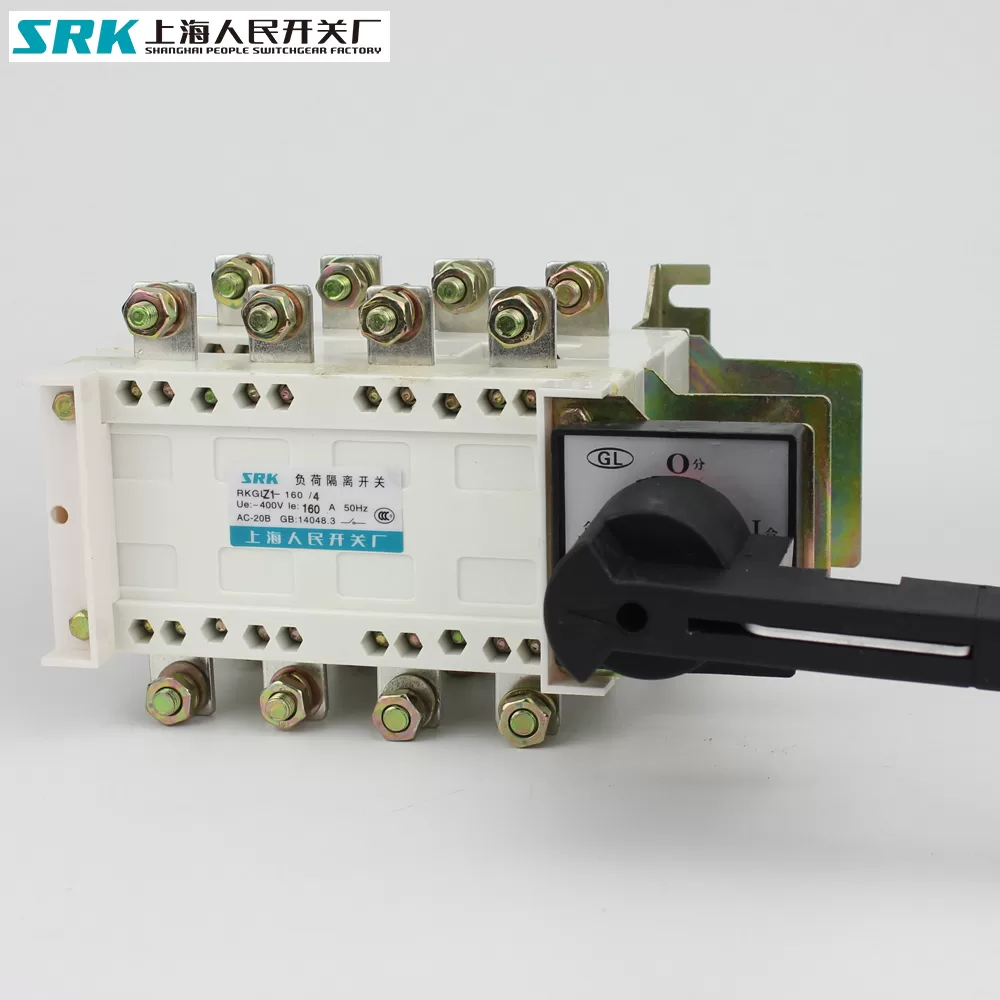

Contact us:

Kani Xie

SHANGHAI PEOPLE SWITCHGEAR FACTORY

E-mail:Kani@srkswitchgear.com

Ph: 0086 13695872200

Wechat/ WhatsApp/skype: +86 13695872200