Electric circuit breakers are the most common protectors in electrical equipment that can protect electrical appliances under the conditions such as short circuit, pressure loss, overload, and melting. The circuit breakers are divided into high -pressure circuit breakers and low -voltage circuit breakers according to their use range. The level of high and low voltage lines is relatively vague. Generally, 3KV or more is called high -voltage appliances.

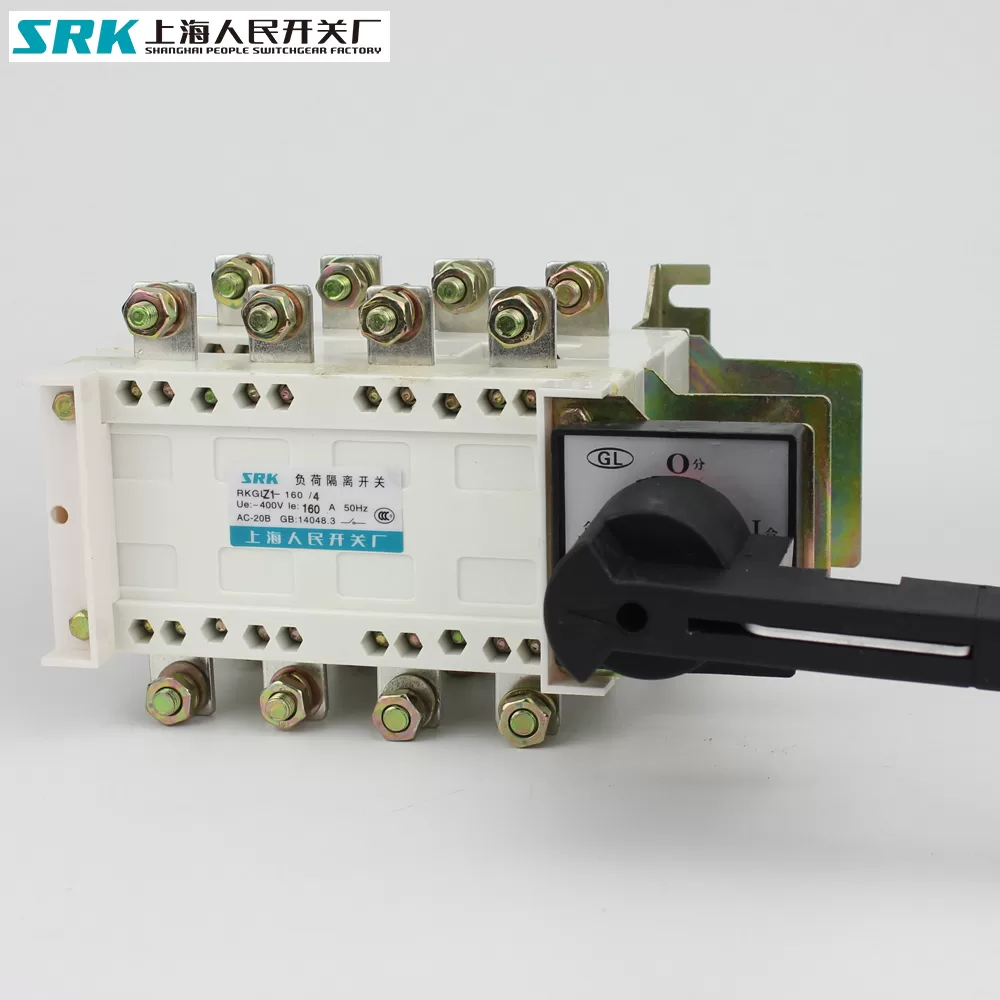

The circuit breaker is generally composed of the contact system, arc extinguishing system, operating mechanism, deedr, shell, etc.

Electric broken circuit can be divided into frame -type circuit breakers, plastic shell circuit breakers, micro -circuit breakers, vacuum circuit breakers, etc. The application of frameworks is the most widely used. When the lines of short circuit, pressure loss, leakage, grounding, etc. occur, the power off is automatically disconnected to play a total switching role. Plastic shell -type circuit breakers can not only achieve power -off function, but also achieve isolation and protection functions. It is currently a wide range of electrical circuit breakers. Micro -broken circuit breakers are often used in the construction industry. It is a vacuum circuit breaker that can achieve functional assembly and function. The vacuum circuit breaker uses a vacuum technology to achieve a disconnection function. It has the advantages of small size, light quality, and arc extinguishing systems. It does not need to be maintained. It is widely used in power stations and power plants.

Plastic shell circuit breaker and miniature circuit breaker

Because plastic has good insulation performance and plasticity, it is often used in the shell, arc extinguishing system and spray port of electrical circuit breakers. Plastic applied to different components requires different performance. If it is used for the shell of electrical circuit breakers, it is necessary to have conditions such as good ductility, good flame retardant performance, good insulation performance, low production cost, energy saving and environmental protection; The characteristics of high dielectric strength and medium recovery strength; plastic for electrical circuit breaker protective components requires the insulation capacitance function, and can separate the conductors of different potentials.

Common engineering plastics, such as PA, PBT, PTFE, POM, etc., are widely used in the field of electrical circuit breakers. However, with the rapid development of the electrical industry, higher requirements for the function, selection, and performance of the electrical circuit breakers, especially for low -voltage circuit breakers, high -electric insulation flame retardant ranges, the appearance, mechanical performance, flame retardant of plastic, flame retardant Performance, environmental protection and energy conservation are higher.